Equipment Overview:

The high temperature furnace adopts the open-type integrated structure and controls the temperature in three sections。The inner wall of each part of the shell of the furnace body is equipped with a ring insulation material,Form a ring heating chamber,The electric furnace wire is divided into three sections: upper, middle and lower,Each section of electric furnace wire is connected through a contact point arranged on the surface of the insulation material,The furnace body is provided with upper, middle and lower thermocouples,Each section of electric furnace wire is heated by a temperature controller and the temperature in the furnace body is collected by a thermocouple。

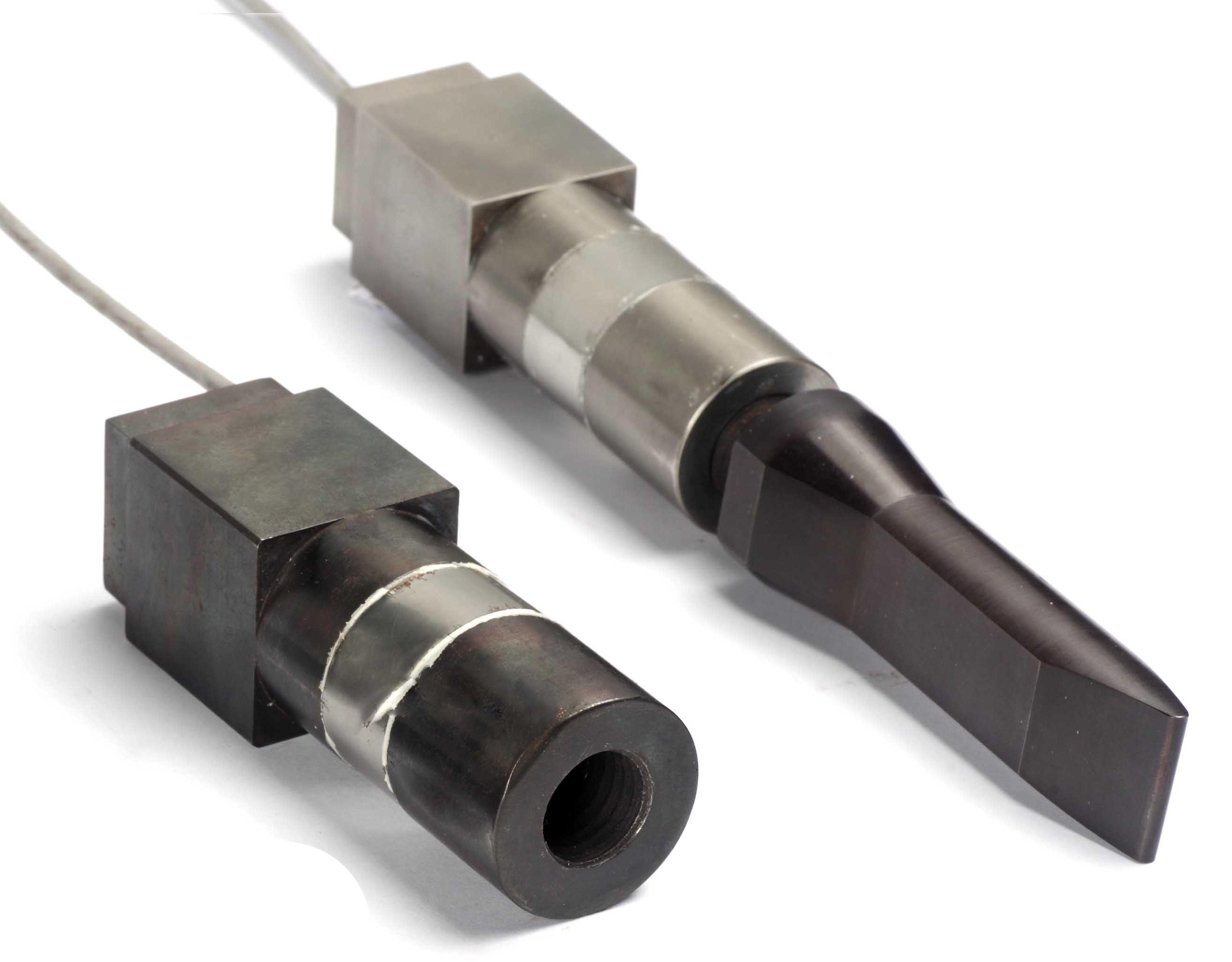

The high temperature furnace is composed of high temperature furnace, intelligent PID temperature controller, high temperature tie rod, high temperature chuck, high temperature extension measuring system and high temperature furnace bracket。The temperature is controlled by SSR output combined with PID fuzzy control,It has self-tuning function,The 485 industrial communication bus module communicates with the computer,The temperature of the thermostat can be set and read directly by the computer,Temperature control is more accurate and convenient,Fast heating speed,It can make the temperature in the furnace rise evenly,The test temperature overshoot is small,High control precision,It is a high performance material test equipment for colleges and universities, scientific research institutions, factories and mining materials research units。It can be used in any combination with the host according to the requirements of the use environment, and can complete the high temperature tensile test of a variety of metals and non-metals, and can meet the requirements of various industries。When doing normal temperature test, just remove the high temperature furnace, which can fully meet GB/T228.2-2015, HB5195-1996, requirements for strength inspection of round rod patterns, rectangular samples, etc. at special ambient temperatures。

The equipment can heat multiple high temperature furnaces at the same time after loading the sample, thus improving the test efficiency。The No. 1 high temperature furnace can be adjusted to the working area of the testing machine before heating, and the upper and lower joint of the tie rod can be inserted into the switching device, and the high temperature furnace can be locked after tying the thermocouple。The test can be started automatically after the test temperature is reached and the corresponding time is kept。After the test of No. 1 high temperature furnace, pull out the extension meter and rotate to one side, push No. 1 high temperature furnace out of the test area, and then push No. 2 high temperature furnace into the test area, and make the upper and lower joint of the tie rod stuck into the adapter, and start the test after meeting the test requirements。

Performance characteristics:

1, the high temperature furnace adopts the cylinder type split structure, the resistance wire heating, by controlling the heating time percentage, to achieve the temperature control accuracy。

2, the temperature controller adopts advanced control mode, the whole process of the test temperature is not impulsive, and the fluctuation is small。

3, the high temperature furnace device is equipped with a movable bracket, the high temperature furnace is pushed into the test space during the test, and the high temperature furnace can be moved away during the normal temperature test。

4, the high temperature furnace rotating bracket adopts a special structural design scheme, so that the furnace body rotation is easy, accurate and reliable positioning, and the use is particularly convenient。

Technical parameters: